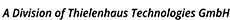

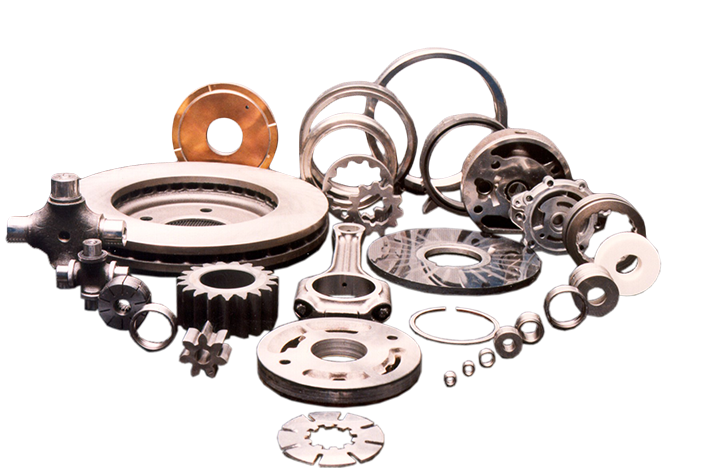

Work pieces are machined on the double-disc grinding machine using a through-feed, plunge-cut or oscillation process, depending on the respective requirements. The compact and rigid machine configuration ensures the greatest level of component precision with the shortest transfer times.

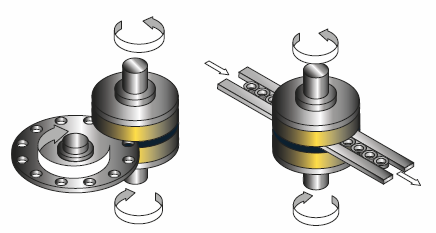

Through-feed process radial/linear for the shortest transfer times

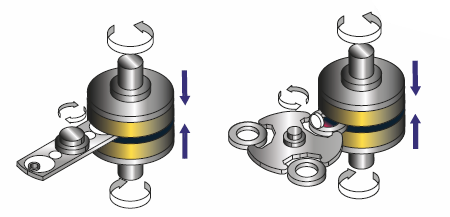

Plunge-cut process, oscillation/rotation for high-end quality with parallel standing tool spindles; removal is done via the in-feed of one of the discs: