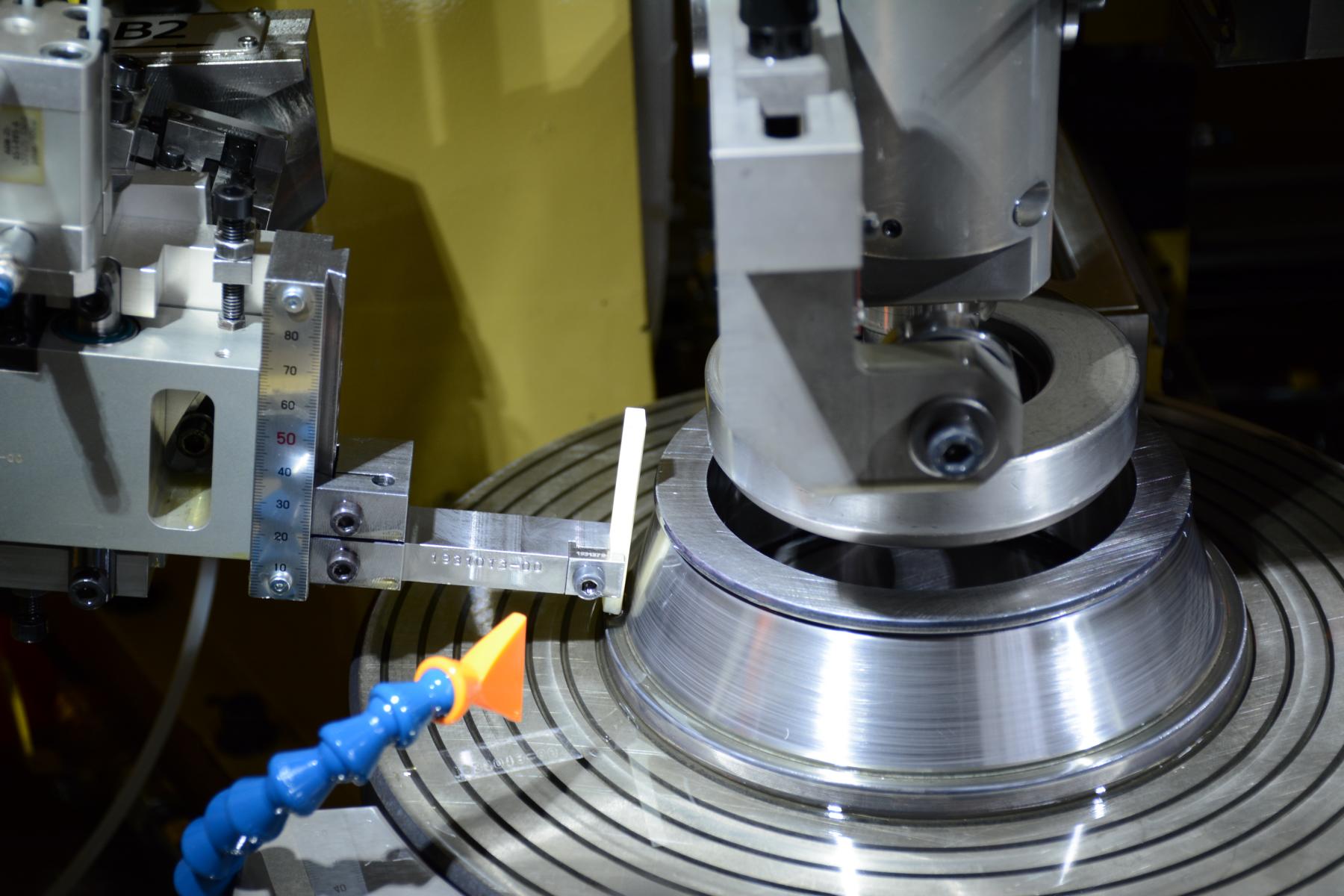

BearingStar is the platform for Microfinish / Superfinish of ball and roller bearing raceways

The surface precision machining of anti-friction bearings must be performed efficiently and flexibly in today’s world, all the while ensuring the highest levels of quality. BearingStar represent a modern, modular machine solution which has been designed specifically for these objectives.