-

BearingStar MiniMehr erfahren

BearingStar MiniMehr erfahrenWorkpiece diameters:

5 - 19 mm

Workpiece width:

2,5 - 15 mm

Single step method -

BearingStar 90Mehr erfahren

BearingStar 90Mehr erfahrenOuter diameter of outer ring:

26 – 90 mm

Inner diameter of inner ring:

10 – 50 mm

Ring width: 8 – 55 mm -

BearingStar 200Mehr erfahren

BearingStar 200Mehr erfahrenOuter diameter of outer ring:

85 – 200 mm

Inner diameter of inner ring:

50 – 180 mm

Ring width: 15 – 80 mm -

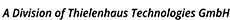

BearingStar 320Mehr erfahren

BearingStar 320Mehr erfahrenOuter diameter of outer ring:

180 – 320 mm

Inner diameter of inner ring:

100 – 270 mm

Ring width: 60 – 200 mm -

BearingStar 650Mehr erfahren

BearingStar 650Mehr erfahrenOuter diameter of outer ring:

200 – 650 mm

Inner diameter of inner ring:

180 – 580 mm

Ring width: 20 – 300