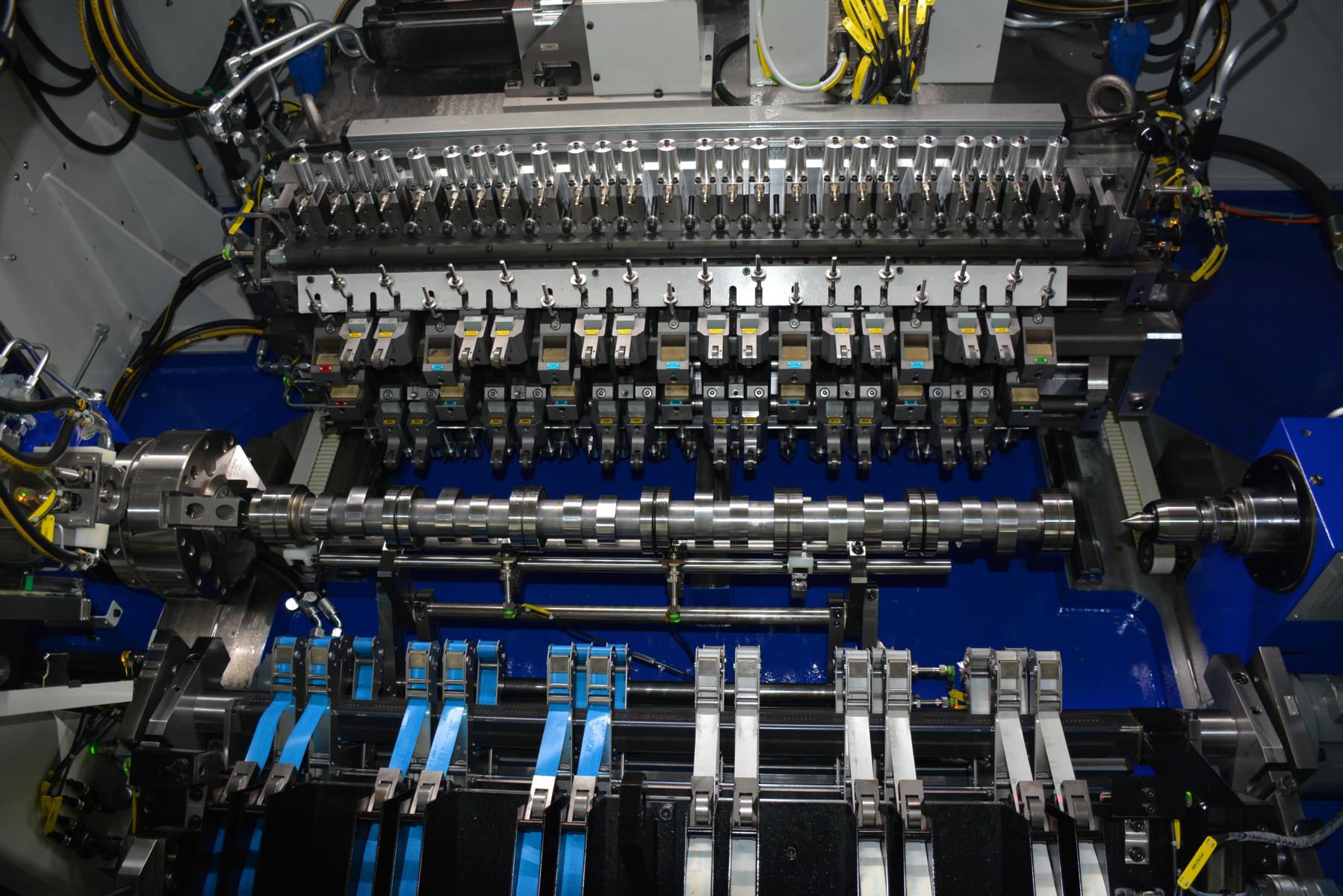

Microfinish / Superfinish of wave-shaped parts with mounting between the centres

Thielenhaus CenterStar is the platform for the Microfinish / Superfinish machining of shafts for mounting between centres. Whether your process involves tape finishing or stone finishing, the modular design enables the machining of almost all shaft types. The mounting systems include, among other things, chucks and collets, both with and without lunette stabilisers. We also offer the machine concept in a special centreless design.