Double-disc grinding with machines from Thielenhaus and Thielenhaus-c

Flat and stamped parts are machined on the double-disc grinding machine using a through-feed, plunge-cut or oscillation process, depending on the respective requirements.

Flat and stamped parts are machined on the double-disc grinding machine using a through-feed, plunge-cut or oscillation process, depending on the respective requirements.

The scope of application for the “V” vertical series is extremely versatile. Depending on the requirements, stamped and flat parts are machined using a plunge-cut, through-feed or oscillation process. The uniquely compact and rigid machine configuration affords the user extreme component precision with very short transfer times.

The Thielenhaus-Nissei series comprises a wide variety of machine sizes in line with the respective operator requirements. Diverse dressing and bond reversal technologies round off the product offering.

Thielenhaus brings together more than 40 years of experience in the manufacturing of double-disc grinding machines with the TwinStar universal machine concept. The TwinStar is at the cutting edge of technology In terms of its design and the materials used, making removal rates of up to 1 mm in < 5 seconds possible when machining automotive connecting rods.

Work pieces are machined on the double-disc grinding machine using a through-feed, plunge-cut or oscillation process, depending on the respective requirements. The compact and rigid machine configuration ensures the greatest level of component precision with the shortest transfer times.

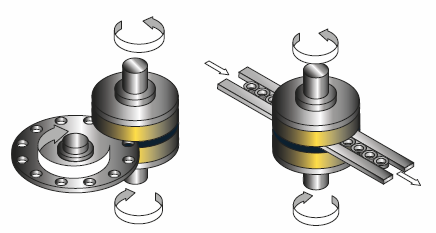

Through-feed process radial/linear for the shortest transfer times

Double-disc grinding product brochure (PDF)

Thielenhaus Sales Department

▶ Phone: +1 248-347-1611

|