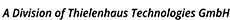

The MicroStar EVO(lution) 1200 sets a new benchmark in combination precision machining. It continues the successful rotary table concept of the 200 MicroStar series, but also possesses 12 stations for the extremely precise and yet more efficient machining of surfaces and geometries. The large number of stations allows a broad range of process combinations to be achieved, such as, for example, double-sided flat finishing, exterior and/or cylindrical grinding, interior grinding, honing and deburring.

Your benefits:

- Savings on additional machines and aggregates thanks to parallel machining by two different tool types

- Maximum productivity thanks to peak time-neutral multiple loading of up to four stations simultaneously

- Highest degree of process and operational reliability thanks to MicroSens force-regulating feed technology and guided EasyTilt tool installation

- High level of flexibility thanks to the modular design and potential to integrate further machining processes

- Extremely high work piece quality through the avoidance of in-process clamping defects since the work pieces are held in one clamping operation for all machining steps

Work area

- Work piece height: max. 230 mm

- Work piece diameter: max. 200 mm