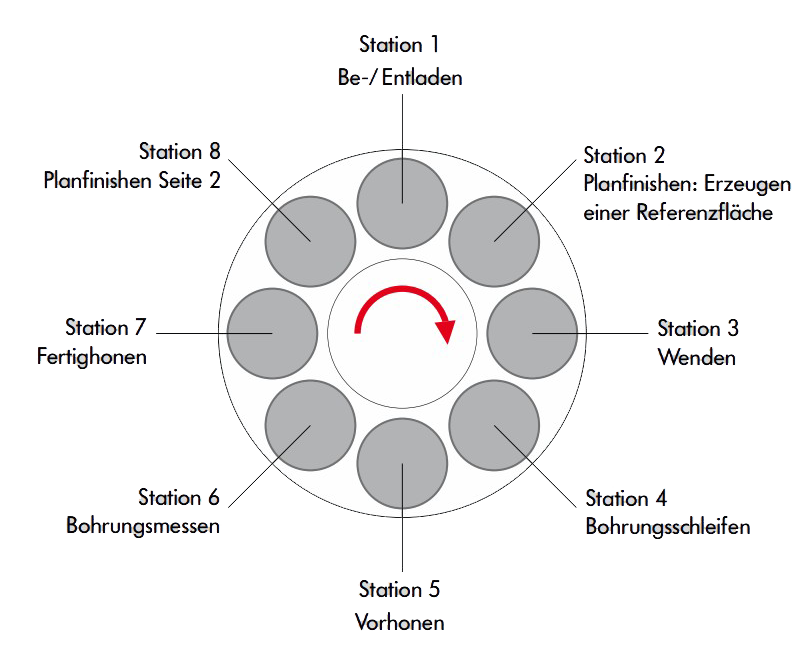

With the MicroStar EVO it’s not only possible to combine different machining processes, but also to increase the production volume. Developed for process combinations or multiple loading, the MicroStar EVO is suitable for machining the following work pieces:

- Synchronising wheels

- Planetary wheels

- Injector parts

- Sensors, etc. (up to 250 mm of swing diameter)

Your benefits:

- 12 stations for up to 11 simultaneous machining processes on one machine with peak time-neutral loading/unloading

- Combination machining such as e.g. flat finishing, internal grinding, cylindrical grinding, honing, deburring, etc.

- Machining in one clamping operation for the narrowest tolerances

- Ensuring the highest level of process and operational reliability through innovative technology for managed tool installations and force control (MicroSens, ToolSens, etc.)

- Multiple loading of up to 4 work pieces simultaneously for the greatest level of productivity within the smallest space

- Excellent accessibility thanks to the rotary table concept with centrally located machine column