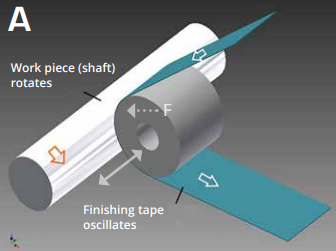

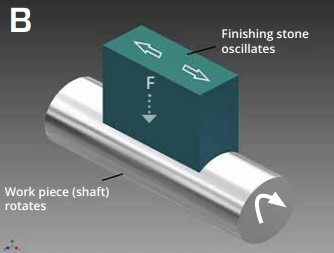

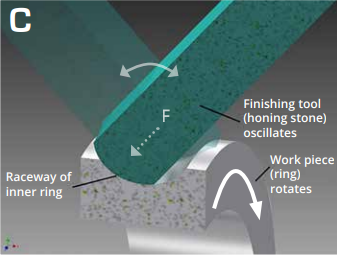

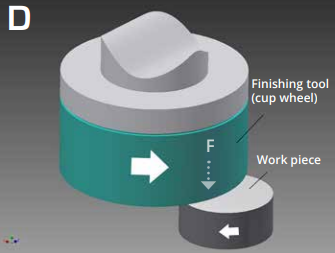

Tape and stone finish

Tape and stone finish with Thielenhaus machines

Our wide range of tape finishing machines can meet the most diverse requirements – whether the customer demands productivity, quality, flexibility or efficiency.

Our wide range of tape finishing machines can meet the most diverse requirements – whether the customer demands productivity, quality, flexibility or efficiency.